Cellulose Nanofibre – The New Alternative to Plastic

Submitted by: The Two Sides Team April 26, 2019

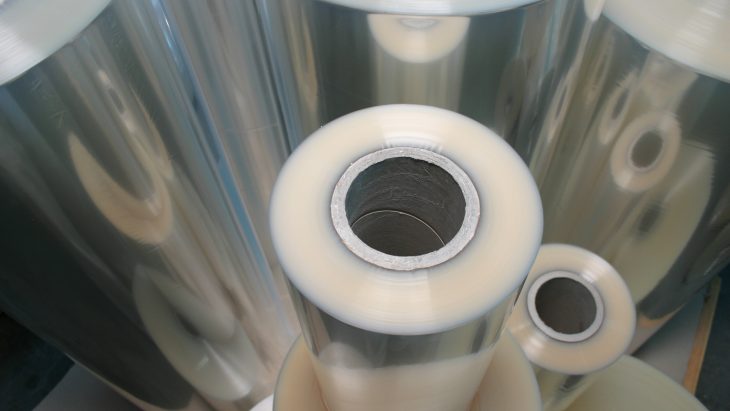

We take a microscopic look at the sustainable and recyclable material derived from wood pulp that could replace plastic packaging.

There’s little doubt that single-use plastics are now high on the list of concerns for governments, businesses and individuals alike. The level of media attention coupled with disturbing images of the oceans becoming dumping grounds for the world’s waste is making everyone sit up and take notice of the global plastics problem.

With such a groundswell of opinion and protest, there’s now an urgent race to create a sustainable material that could replace traditional plastic packaging. Of course, paper and card are a fantastic resource, with their high recycling rate, adaptability and protective properties, but there’s still a gap for a strong, sustainable material with barrier and translucent properties – which is where cellulose nanofibre comes in.

Advanced biomass material

Cellulose nanofibre is being hailed as the world’s most advanced biomass material. As the building block of wood fibre, it’s environmentally friendly both in its production and disposal, and there’s no shortage of the core material.

Once created, cellulose nanofibre exhibits many of the characteristics of plastic: it’s lightweight, strong and transparent, with high barrier properties to water and gas. As such, it’s seen as an exciting alternative to plastic not just in food packaging, but also in medicine, cosmetics and even as a sustainable material for screens in electronic devices.

“The beauty of this material is that it is so abundant we don’t have to make it”

“We have been looking at cellulose nanocrystals for several years and exploring ways to improve those for use in food packaging,” said James Meredith, a professor at the Georgia Institute of Technology, just one of the academic and business institutions around the world looking at developing cellulose for commercial use. “There’s a huge market opportunity for renewable and compostable packaging, an area that’s going to become more important as the population continues to grow.”

A variety of uses

The material is created by taking the raw material of wood chips and mechanically pulping them to create wood fibres. These fibres can then be chemically treated to create cellulose nanofibre. Once you have the nanofibres, these can have a huge variety of uses. As well as an effective replacement for plastic packaging, it could also be used to replace car parts and computer components, while some research teams are even using it to develop lightweight body armour and bulletproof glass.

The first cellulose nanofibre was actually produced back in 1983, but commercial production didn’t start until 2010, mainly due to the high production energy consumption and production costs. But now those costs have come down, a number of companies have sprung up around the world, from Japan to Canada, Finland to France, looking to cash in on this ‘wonder material’.

Wood waste into gold

Of course, the big advantage of cellulose nanofibre is the fact that it comes directly from trees and is entirely compostable and biodegradable. If its development continues at the current pace, many say it could make non-organic plastics obsolete in the very near future.

“The beauty of this material is that it is so abundant we don’t have to make it,” says Jeff Youngblood of Purdue University’s NanoForestry Institute in Indiana. “We don’t even have to use entire trees. If we wanted we could use twigs and branches or even sawdust. We are turning waste into gold.”